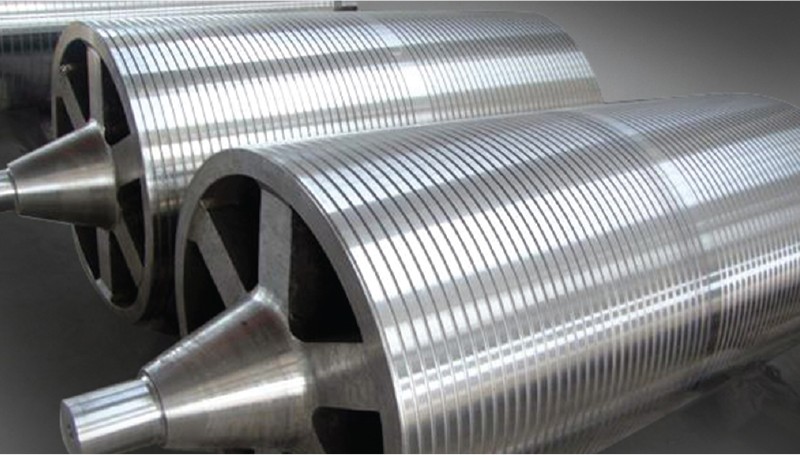

Steel Rolls for Galvalume Industry

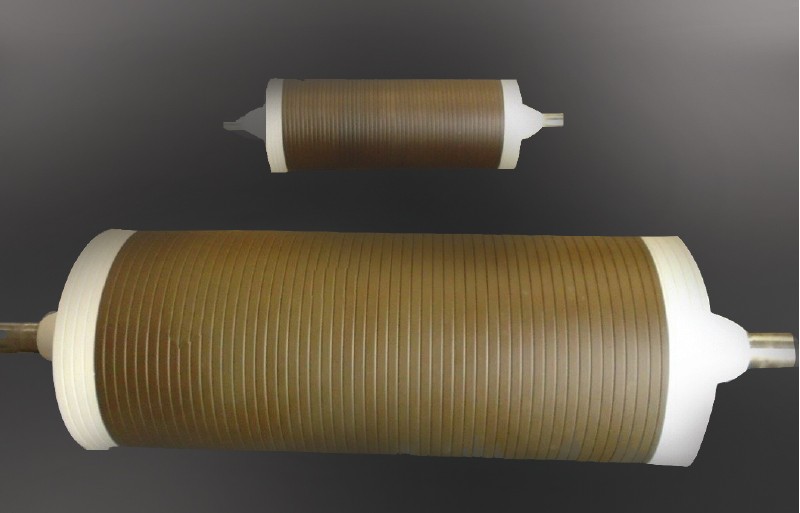

Stucco-25 is a breakthrough thermal spray technology, developed and optimized through years of research

and trials to protect sink and stabilizer rolls. The unique coating by HVOF process makes use of customized

powder to protect galvanizing equipment that operates in corrosive zinc and zinc-alum solutions.

Features

- Application of customized powder with precise metallurgy

- No erosion or corrosion on the working surface

- Coated rolls do not produce scrape for the full term of the coating

- Special paint on the side flanges to prevent slag/dross

- Surface roughness maintained during process, which helps in sink roll rotation

- Low maintenance

- Surface cleaning with acid is not required up to 5 cycles. A diluted solution of acid is used for quick cleaning when required

- The coating doesn’t get damaged with prolonged storage

Performance & advantages

- Lifespan of Stucco-25 coating is 7 to 9 cycles (over 100 days with each cycle consisting of 15 to 21 days)

- Lifespan of Stucco-25 coating in Galvalume solution is 12 to 14 cycles (over 150 days, subject to bearing bush and sleeve life)

- Unparalleled technology (the closest is HVOF 88/12 cobalt sealed with acid, offering a lower lifespan)

- Stucco-25 will not delaminate

- Coated surface is free from groove line mark

- Recoating of the rolls is done with the least base material loss of

- 0.2mm, thus increasing its operational life by 2-3 times

Other applications

|

|

|

|

|

|

-

Steel Rolls for Galvalume Industry

-

Steel Rolls for Galvalume Industry